- PCD for Cutting Tool

-

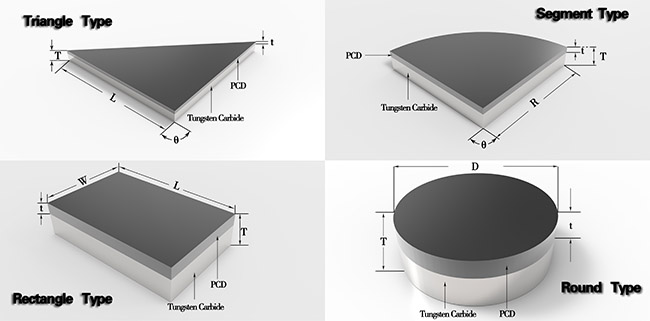

- The PCD for Cutting Tool is higher quality diamond micro powder sintering tungsten carbide at very high temperature and pressure, which press chamber is much larger than that of PDC. Generally, the thickness of diamond layer is 0.5mm, and the largest diameter could reach 48mm.

- PCD products apply to processing non-metal materials like timber, aluminum alloy, copper alloy, ceramic, cemented carbide, carbon-fiber composites and nonferrous metals, and also apply to various wear parts fabrication.

Type Value MC25--A MC25--B MC10--A MC10--B Diameter (mm) 48.0 48.0 48.0 48.0 Total Thickness (mm) 1.6/2.0/3.2 1.6/2.0/3.2 1.6/2.0/3.2 1.6/2.0/3.2 Diamond Layer (mm) 0.5 0.5 0.5 0.5 Grain Size (μm) 25 25 10 10 Diamond (vol.%) 95 90 95 90 Wear Resistance Ratio ( X 100,000) ≥

Impact Toughness (J) ≥300 ≥400 ≥500 ≥600 Characteristics Over 95% diamond content, with very high abrasion resistance and long life time.With both high abrasion resistance and impact toughness, apply to larger feed application.High abrasion resistance, high impact toughness and surface finishing.Well abrasion resistance, high impact toughness and surface finishing, apply to larger feed application.Application Ceramic, hard alloy, carbide and other high-abrasive materials and wear parts fabrication.High-silicon aluminum alloy, timber, glass, ceramic and other high-abrasive materials. Wear parts fabrication.Silicon aluminum alloy, timber, organic glass, ceramic and nonferrous metal.Silicon aluminum alloy, timber, organic glass and nonferrous metal, etc.Processing Method Laser cuttingLaser cutting or wire cuttingLaser cuttingLaser cutting or wire cutting